Click Category below to explore relevant FAQ’s

Basic Operation

Expiration dates in the BestCode Series 8 are called AutoCodes. Follow the video here to add either Realtime Codes or AutoCodes.

Watch this video on YouTube

Product Counter is in the Advanced Editing Menu. Follow the video instructions to see how to add a counter into your message

Watch this video on YouTube

This could be a couple of things.

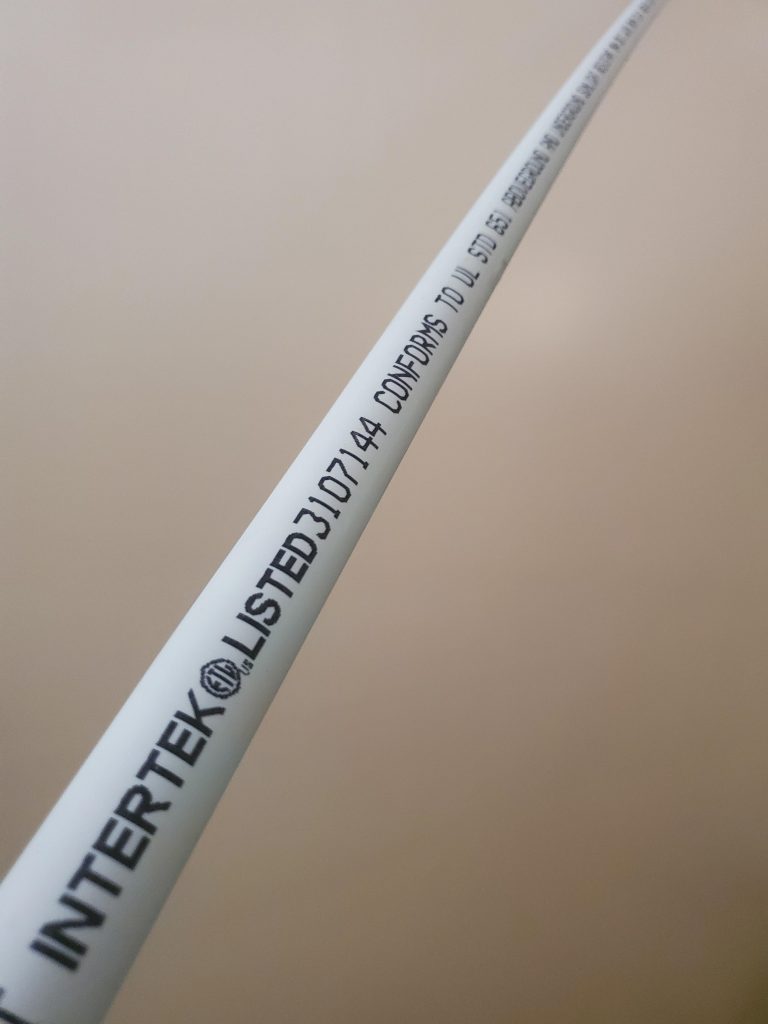

1. Check the photocell to make sure that the light on the back of it is turning on and off as the product goes past. If you are using the Banner Proximity then the yellow power light should be on and the orange detect light should flash on and off as a product goes past. Watch the video below on how to afjust the photocell if thats not the case.

2. If you are running a variable speed shaft encoder, it could be that the encoder wheel has lost connection to the belt and is not rotating. The wheel needs to rotate at the speed of the belt to monitor the speed of the belt.

3. It could be that the Product Delay is set to early or too late and it is actually printing but off the product. Try holding a piece of paper in front of the head and give a print go manually using the button at the top of the Service Menu.

Watch this video on YouTube

First thing to do is to create the message you want to print. Insert any text and logos you need.

Once the message is created, while in the edit message screen click on the Advanced button and go to Print Mode. In the top left now you can select between Auto Select, Repeat print and Autoprint functions. Select Autoprint and set the Delay for the first print and the Pitch which sets up the space between the prints.

A tip on this, if you are not using a shaft encoder and the product is moving very slow you may need to increase the Width up to around 100 and the pitch up around 30,000 to get the spacing required.