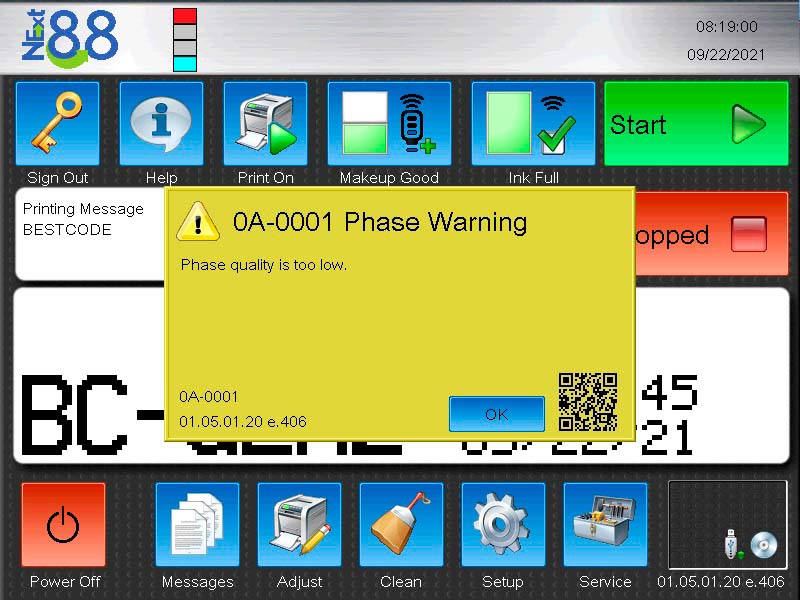

0A-0001

The Phase is Low

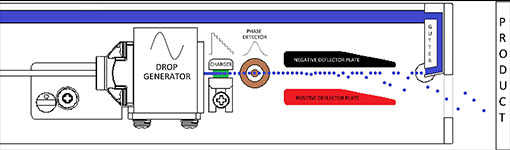

The drop generator creates 65,000 droplets per second. A restriction in flow or pressure change can result in less charged droplets passing through the detector causing a low phase fault. A sensor blocked with dried ink will not be able to detect the droplets either.

Diagnosing the Issue

It is difficult to identify the exact cause of phase issues. The phase detector in the printhead is measuring the applied voltage to the droplets. It is looking at the charge and the time in which droplets pass through.

Begin diagnosis by checking the viscosity of the ink. From the Home Screen go into Service. The bottom right of the screen will read “Target Viscosity 4.5 and Actual Viscosity __”. A viscosity lower than 4.0 or higher than 5.0 must be addressed first.

Re-calibrate modulation once you have verified that the viscosity is within range.

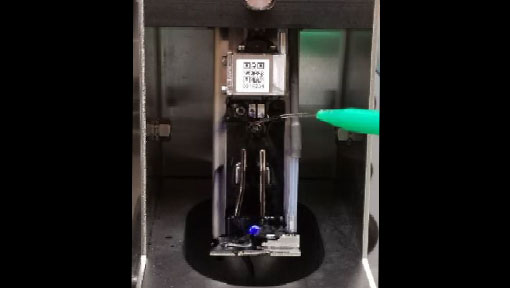

Cleaning Ink Build up on the Phase Detector

Place the printhead into the cleaning station (Part# 40-0020-01 Kit, Printhead Clean Station). Use the correct cleaner for the ink type that is being used. Clean any traces of ink from the top in this order—the charge electrode, phase detector, deflection plates, return gutter and printhead slot.

Restriction in Flow Caused by a Blocked Filter

A blocked filter may be the problem if you still have a “phase low” error after cleaning the printhead. Test the flow of ink into the drop generator. Low pressure at the drop generator can cause bad starts or phase issues.

Remove the Drop Generator nozzle. Run the pump with the printhead valve on. A strong flow of ink should come out of the drop generator at 15 RPS. If the flow is weak there is an obstruction between the Pump and the Nozzle.

Test the Pump, the Filter, the Venturi, the Green Tube, the Ink Manifold, the Red Tube, the Dampener, the Printhead Valve Manifold, Printhead Valve and Drop Generator for obstructions.

Run the pump with no valves on. The Printhead three way valve is not fully closed if ink comes out of the drop generator and is allowing ink to exit. Replace the Printhead three-way valve.

Check on the printer to see when the last PM (Preventative Maintenance) Filter change was completed. Perform a complete filter change including the Makeup Filter, the Pre-Pump Filter and Dampener. The printer measures “Run Hours” which is the time that the jet is turned on. It does not account for dusty environments where the filter may be clogging quicker. Consider adding Positive Air to the printer to keep dust out and lengthen the filter life.

04

Component Failures

If you still have a low phase fault then it is most likely due to a component failure of either the CPU or Umbilical Assembly.