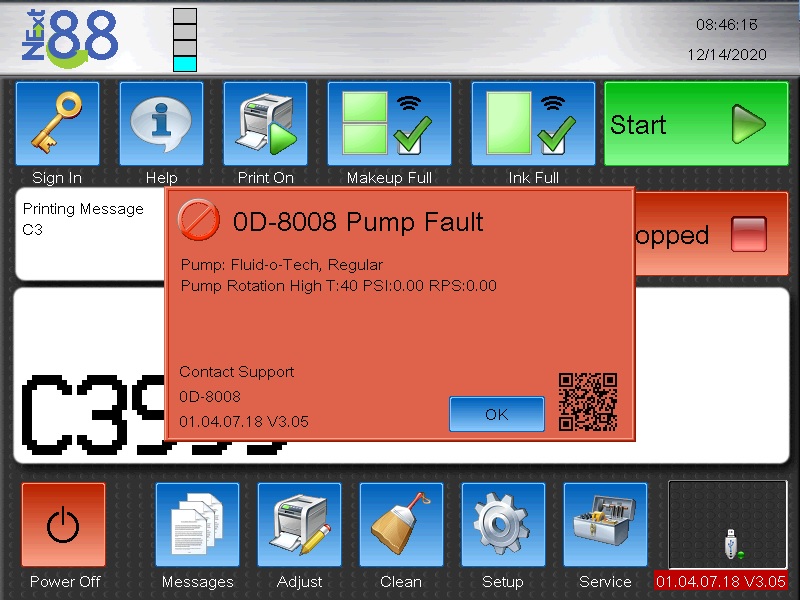

0D-8008

Pump Rotation High

This fault is caused by higher than expected pump rotations which is typically due to an air leak The pump is working harder to maintain the right pressure. The pump needs to be rotating no less than 18 to 20RPS to achieve the necessary 40PSI.

Bypassing the Filters

Confirm the right pump has been selected in the software. It is important to check this because there are several options available.

Air may be getting into the system if the pump is rotating too high and hot to the touch. This typically occurs if a Main or Pre-pump Filter has been installed incorrectly. Check the fittings to make sure they have not been cross-threaded.

Bypass the filters by connecting a tube directly from the pump. Place the other end of the tube in a beaker. Start the pump manually increasing until there is a flow of ink. The issue will be the pump if there is no ink flow. Replace the pump.

Check tubing on Venturi

Ensure that the tubing is correct on the venturi. Watch the video to see how to clean the venturi and also the correct placement of tubes.

03

Faulty Pump

On very rare occasions it has been known for the pump to wear so the impellers are not pushing fluid anymore. This is typically found in very harsh environments like cement works where the abrasive dust has got into the ink system and slowly worn away the impellers. Replace the pump but also address the dust issue by suggesting positive air system.

04

Faulty CPU

Update the firmware. The fault will be on the CPU if steps one through three did not correct the fault warning. Replace the CPU board if the firmware update is not the issue.