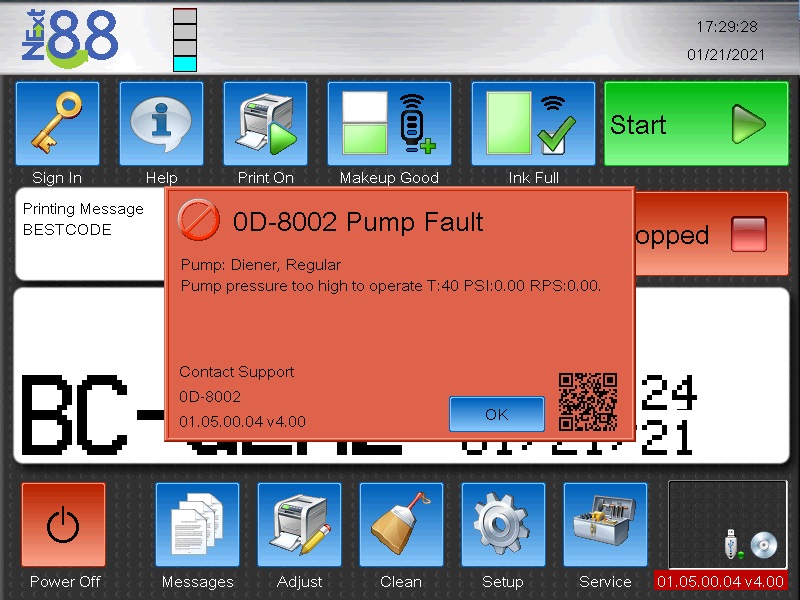

0D-8002

Pump Pressure Too High

This fault is caused by pressure in the system exceeding the maximum level permitted. The pump needs to be rotating no less than 18 to 20RPS to achieve the necessary 40PSI.

PHP DEPRECATED: wp_make_content_images_responsive is deprecated

Stack trace:

#0 /home/bestcodevps/support.bestcode.co/wp-includes/deprecated.php(4013): _deprecated_function() Arguments ["wp_make_content_images_responsive","5.5.0","wp_filter_content_tags()"]

#1 /home/bestcodevps/support.bestcode.co/wp-includes/class-wp-hook.php(324): wp_make_content_images_responsive() Arguments ["<p>[et_pb_section fb_built=\"1\" _builder_version=\"4.4.8\" background_color=\"#f2f2f3\" global_module=\"103\" saved_tabs=\"all\"][et_pb_row column_structure=\"1_5,1_5,1_5,1_5,1_5\" use_custom_gutter=\"on\" make_equal=\"on\" _builder_version=\"4.4.8\" background_color=\"rgba(0,0,0,0)\" width=\"100%\" max_width_tablet=\"\" max_width_phone=\"100%\" max_width_last_edited=\"on|phone\" module_alignment=\"center\" custom_margin=\"-33px||-22px||false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|phone\" custom_padding=\"38px|0px|29px|7px|false|false\" link_option_url_new_window=\"on\" module_alignment_tablet=\"center\" module_alignment_phone=\"\" module_alignment_last_edited=\"on|desktop\"][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\" link_option_url_new_window=\"on\"][et_pb_button button_url=\"mailto:info@bestcode.co\" url_new_window=\"on\" button_text=\"Email BestCode\" button_alignment=\"center\" _builder_version=\"4.4.8\" custom_button=\"on\" button_text_size=\"13px\" button_bg_color=\"#1f3a7c\" button_border_width=\"2px\" button_border_color=\"#dfdfdf\" button_border_radius=\"15px\" button_letter_spacing=\"2px\" button_font=\"PT Sans Caption|700|||||||\" button_icon=\"%%238%%\" button_icon_color=\"#adc837\" button_icon_placement=\"left\" button_on_hover=\"off\" background_layout=\"dark\" custom_margin=\"7px|||0px|false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|phone\" custom_padding=\"7px|9px|6px|26px|false|false\"][\/et_pb_button][et_pb_text content_tablet=\"<\/p>\n<h3 style=%22text-align: center;%22>Coding and Marking Solutions<\/h3>\n<p>\" content_phone=\"<\/p>\n<h3 style=%22text-align: center;%22>Coding and Marking Solutions<\/h3>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_3_font=\"|700|||||||\" header_3_text_color=\"#1f3a7c\" header_3_line_height=\"1.1em\" custom_margin=\"||7px|||\" custom_padding=\"||0px|||\" link_option_url=\"https:\/\/www.bestcode.co\/\" link_option_url_new_window=\"on\"]<\/p>\n<h3 style=\"text-align: center;\">Coding and Marking Solutions<\/h3>\n<p>[\/et_pb_text][et_pb_button button_url=\"https:\/\/www.bestcode.co\/\" url_new_window=\"on\" button_text=\"www.bestcode.co\" button_alignment=\"center\" _builder_version=\"4.4.8\" custom_button=\"on\" button_text_size=\"13px\" button_bg_color=\"#1f3a7c\" button_border_width=\"2px\" button_border_color=\"#dfdfdf\" button_border_radius=\"15px\" button_letter_spacing=\"2px\" button_font=\"PT Sans Caption|700|||||||\" button_use_icon=\"off\" background_layout=\"dark\" custom_margin=\"7px|||0px|false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|phone\" custom_padding=\"7px|9px|7px|15px|false|false\"][\/et_pb_button][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_text content_tablet=\"<\/p>\n<h2 style=%22text-align: center;%22>About BestCode<\/h2>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/company%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Company<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/tradeshows%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Tradeshows<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/news%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>News<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/application-videos%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Application Videos<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/privacy-policy%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Privacy Policy<\/a><\/p>\n<p>\" content_phone=\"<\/p>\n<h2 style=%22text-align: center;%22>About BestCode<\/h2>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/company%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Company<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/tradeshows%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Tradeshows<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/news%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>News<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/application-videos%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Application Videos<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/privacy-policy%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Privacy Policy<\/a><\/p>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" text_font=\"PT Sans|600|||||||\" text_text_color=\"#1f3a7c\" text_letter_spacing=\"1px\" text_line_height=\"1em\" header_font=\"PT Sans Caption|||on|||||\" header_text_align=\"center\" header_text_color=\"#b6b6b6\" header_font_size=\"16px\" header_2_font=\"PT Sans Caption|||on|||||\" header_2_text_color=\"#919191\" header_2_font_size=\"14px\" custom_padding=\"|||1px|false|false\" custom_padding_tablet=\"\" custom_padding_phone=\"\" custom_padding_last_edited=\"on|phone\" link_option_url_new_window=\"on\"]<\/p>\n<h2 style=\"text-align: center;\">About BestCode<\/h2>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/company\" target=\"_blank\" rel=\"noopener noreferrer\">Company<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/tradeshows\" target=\"_blank\" rel=\"noopener noreferrer\">Tradeshows<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/news\" target=\"_blank\" rel=\"noopener noreferrer\">News<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/application-videos\" target=\"_blank\" rel=\"noopener noreferrer\">Application Videos<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/privacy-policy\" target=\"_blank\" rel=\"noopener noreferrer\">Privacy Policy<\/a><\/p>\n<p>[\/et_pb_text][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_text _builder_version=\"4.4.8\" text_font=\"PT Sans Caption|600||on|||||\" text_text_color=\"#1f3a7c\" text_letter_spacing=\"1px\" text_line_height=\"1em\" header_font=\"PT Sans||||||||\" header_text_align=\"center\" header_text_color=\"#b6b6b6\" header_font_size=\"18px\" header_2_font=\"PT Sans Caption||||||||\" header_2_text_align=\"center\" header_2_text_color=\"#919191\" header_2_font_size=\"14px\" text_orientation=\"center\" custom_padding=\"||8px||false|false\" link_option_url_new_window=\"on\"]<\/p>\n<h2 style=\"text-align: center;\">Follow BestCode<\/h2>\n<p>[\/et_pb_text][et_pb_social_media_follow _builder_version=\"4.4.8\" text_orientation=\"center\" custom_margin=\"-36px||||false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|desktop\"][et_pb_social_media_follow_network social_network=\"linkedin\" url=\"https:\/\/www.linkedin.com\/company\/bestcode\" _builder_version=\"4.4.8\" background_color=\"#007bb6\" follow_button=\"off\" url_new_window=\"on\"]linkedin[\/et_pb_social_media_follow_network][et_pb_social_media_follow_network social_network=\"instagram\" url=\"https:\/\/www.instagram.com\/bestcode_coding\/\" _builder_version=\"4.4.8\" background_color=\"#ea2c59\" follow_button=\"off\" url_new_window=\"on\"]instagram[\/et_pb_social_media_follow_network][et_pb_social_media_follow_network social_network=\"facebook\" url=\"https:\/\/www.facebook.com\/bestcodecoding\" _builder_version=\"4.4.8\" background_color=\"#3b5998\" follow_button=\"off\" url_new_window=\"on\"]facebook[\/et_pb_social_media_follow_network][et_pb_social_media_follow_network social_network=\"twitter\" url=\"https:\/\/twitter.com\/bestcodecoding\" _builder_version=\"4.4.8\" background_color=\"#00aced\" follow_button=\"off\" url_new_window=\"on\"]twitter[\/et_pb_social_media_follow_network][\/et_pb_social_media_follow][et_pb_text content_tablet=\"<\/p>\n<\/p>\n<h4 style=%22text-align: center;%22>Try-Before-You-Buy Options<\/p>\n<\/h4>\n<p>\" content_phone=\"<\/p>\n<\/p>\n<h4 style=%22text-align: center;%22>Try-Before-You-Buy Options<\/p>\n<\/h4>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_3_font=\"|700|||||||\" header_3_text_color=\"#1f3a7c\" header_3_line_height=\"1.1em\" header_4_font=\"Roboto Condensed|700|||||||\" header_4_text_color=\"#1f3a7c\" header_4_line_height=\"1.1em\" link_option_url=\"https:\/\/www.bestcode.co\/contact\" link_option_url_new_window=\"on\" header_4_font_tablet=\"\" header_4_font_phone=\"\" header_4_font_last_edited=\"on|desktop\" header_4_font_size_tablet=\"\" header_4_font_size_phone=\"\" header_4_font_size_last_edited=\"on|phone\"]<\/p>\n<h4 style=\"text-align: center;\"><a href=\"https:\/\/pei22.nvytes.co\/lp22\/51S27.html\" target=\"_blank\" rel=\"noopener noreferrer\"><\/a>Try Before You Buy Options<\/p>\n<\/h4>\n<p>[\/et_pb_text][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_text _builder_version=\"4.4.8\" text_font=\"|600|||||||\" text_text_color=\"#1f3a7c\" text_line_height=\"1em\" header_font=\"PT Sans||||||||\" header_text_color=\"#b6b6b6\" header_font_size=\"18px\" header_2_font=\"PT Sans Caption|||on|||||\" header_2_text_color=\"#919191\" header_2_font_size=\"14px\" header_2_letter_spacing=\"1px\" module_alignment=\"center\"]<\/p>\n<h2 style=\"text-align: center;\">Associations<\/h2>\n<p>[\/et_pb_text][et_pb_image src=\"https:\/\/support.bestcode.co\/wp-content\/uploads\/2020\/06\/memberPMMI.png\" alt=\"bestcode-pmmi-org-member\" title_text=\"PMMI Member\" url=\"https:\/\/pmmiprod3ebiz.personifycloud.com\/personifyebusiness\/MyAccount\/MemberDirectoryDetail.aspx?companyid=12195911\" url_new_window=\"on\" align=\"center\" src_tablet=\"https:\/\/support.bestcode.co\/wp-content\/uploads\/2020\/06\/memberPMMI.png\" src_phone=\"https:\/\/support.bestcode.co\/wp-content\/uploads\/2020\/06\/memberPMMI.png\" src_last_edited=\"on|phone\" show_bottom_space_tablet=\"\" show_bottom_space_phone=\"\" show_bottom_space_last_edited=\"on|phone\" align_tablet=\"center\" align_phone=\"center\" align_last_edited=\"on|desktop\" _builder_version=\"4.4.8\" custom_margin=\"-21px||||false|false\"][\/et_pb_image][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_blurb title=\"+1 817 349 8555\" use_icon=\"on\" font_icon=\"%%264%%\" icon_placement=\"left\" content_max_width=\"180px\" use_icon_font_size=\"on\" icon_font_size=\"18px\" content_tablet=\"\" content_phone=\"\" content_last_edited=\"on|phone\" content_max_width_tablet=\"\" content_max_width_phone=\"\" content_max_width_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_font_size=\"16px\" custom_margin=\"|0px||0px|false|false\" custom_padding=\"2px|||0px|false|false\" custom_padding_tablet=\"|||0px|false|false\" custom_padding_phone=\"|||0px|false|false\" custom_padding_last_edited=\"on|desktop\" header_text_align_tablet=\"\" header_text_align_phone=\"center\" header_text_align_last_edited=\"on|phone\"][\/et_pb_blurb][et_pb_blurb title=\"+1 817 349 8480\" use_icon=\"on\" font_icon=\"%%268%%\" icon_placement=\"left\" content_max_width=\"180px\" use_icon_font_size=\"on\" icon_font_size=\"18px\" content_max_width_tablet=\"\" content_max_width_phone=\"\" content_max_width_last_edited=\"on|desktop\" _builder_version=\"4.4.8\" header_font=\"PT Sans||||||||\" header_text_align=\"center\" header_font_size=\"16px\" width_tablet=\"\" width_phone=\"\" width_last_edited=\"on|tablet\" custom_margin=\"-14px|0px||0px|false|false\" custom_padding=\"|0px||0px|false|false\" custom_padding_tablet=\"\" custom_padding_phone=\"\" custom_padding_last_edited=\"on|phone\" header_font_tablet=\"\" header_font_phone=\"\" header_font_last_edited=\"on|phone\" header_text_align_tablet=\"\" header_text_align_phone=\"\" header_text_align_last_edited=\"on|tablet\" module_alignment_tablet=\"center\" module_alignment_phone=\"center\" module_alignment_last_edited=\"on|tablet\"][\/et_pb_blurb][et_pb_text content_tablet=\"<\/p>\n<\/p>\n<h4 style=%22text-align: center;%22>In Plant Demonstrations Available<\/h4>\n<\/p>\n<p>\" content_phone=\"<\/p>\n<\/p>\n<h4 style=%22text-align: center;%22>In Plant Demonstrations Available<\/h4>\n<\/p>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_3_font=\"|700|||||||\" header_3_text_color=\"#1f3a7c\" header_3_line_height=\"1.1em\" header_4_font=\"Roboto Condensed|700|||||||\" header_4_text_color=\"#1f3a7c\" header_4_line_height=\"1.1em\" link_option_url=\"https:\/\/www.bestcode.co\/contact\" link_option_url_new_window=\"on\" header_4_font_tablet=\"\" header_4_font_phone=\"\" header_4_font_last_edited=\"on|desktop\" header_4_font_size_tablet=\"\" header_4_font_size_phone=\"\" header_4_font_size_last_edited=\"on|phone\"]<\/p>\n<h4 style=\"text-align: center;\"><a href=\"https:\/\/pei22.nvytes.co\/lp22\/51S27.html\" target=\"_blank\" rel=\"noopener noreferrer\"><\/a>In Plant Demonstrations Available<\/h4>\n<p>[\/et_pb_text][\/et_pb_column][\/et_pb_row][\/et_pb_section][et_pb_section fb_built=\"1\" fullwidth=\"on\" _builder_version=\"4.4.8\" background_color=\"#b6b6b6\" height=\"75px\" height_tablet=\"\" height_phone=\"\" height_last_edited=\"on|phone\" custom_margin=\"||0px||false|false\" custom_padding=\"||0px||false|false\" hover_enabled=\"0\"][et_pb_fullwidth_header title=\"\u00a92024 BestCode | Designed and Manufactured by BestCode in Texas, USA\" _builder_version=\"4.4.8\" title_font=\"PT Sans Caption||||||||\" title_text_align=\"center\" title_font_size=\"13px\" title_line_height=\"1.1em\" background_color=\"#b6b6b6\" custom_margin=\"||0px||false|false\" custom_padding=\"18px||0px||false|false\" hover_enabled=\"0\" title_line_height_tablet=\"\" title_line_height_phone=\"1.7em\" title_line_height_last_edited=\"on|phone\"][\/et_pb_fullwidth_header][\/et_pb_section]<\/p>\n"]

#2 /home/bestcodevps/support.bestcode.co/wp-includes/plugin.php(205): WP_Hook::apply_filters() Arguments ["<p>[et_pb_section fb_built=\"1\" _builder_version=\"4.4.8\" background_color=\"#f2f2f3\" global_module=\"103\" saved_tabs=\"all\"][et_pb_row column_structure=\"1_5,1_5,1_5,1_5,1_5\" use_custom_gutter=\"on\" make_equal=\"on\" _builder_version=\"4.4.8\" background_color=\"rgba(0,0,0,0)\" width=\"100%\" max_width_tablet=\"\" max_width_phone=\"100%\" max_width_last_edited=\"on|phone\" module_alignment=\"center\" custom_margin=\"-33px||-22px||false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|phone\" custom_padding=\"38px|0px|29px|7px|false|false\" link_option_url_new_window=\"on\" module_alignment_tablet=\"center\" module_alignment_phone=\"\" module_alignment_last_edited=\"on|desktop\"][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\" link_option_url_new_window=\"on\"][et_pb_button button_url=\"mailto:info@bestcode.co\" url_new_window=\"on\" button_text=\"Email BestCode\" button_alignment=\"center\" _builder_version=\"4.4.8\" custom_button=\"on\" button_text_size=\"13px\" button_bg_color=\"#1f3a7c\" button_border_width=\"2px\" button_border_color=\"#dfdfdf\" button_border_radius=\"15px\" button_letter_spacing=\"2px\" button_font=\"PT Sans Caption|700|||||||\" button_icon=\"%%238%%\" button_icon_color=\"#adc837\" button_icon_placement=\"left\" button_on_hover=\"off\" background_layout=\"dark\" custom_margin=\"7px|||0px|false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|phone\" custom_padding=\"7px|9px|6px|26px|false|false\"][\/et_pb_button][et_pb_text content_tablet=\"<\/p>\n<h3 style=%22text-align: center;%22>Coding and Marking Solutions<\/h3>\n<p>\" content_phone=\"<\/p>\n<h3 style=%22text-align: center;%22>Coding and Marking Solutions<\/h3>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_3_font=\"|700|||||||\" header_3_text_color=\"#1f3a7c\" header_3_line_height=\"1.1em\" custom_margin=\"||7px|||\" custom_padding=\"||0px|||\" link_option_url=\"https:\/\/www.bestcode.co\/\" link_option_url_new_window=\"on\"]<\/p>\n<h3 style=\"text-align: center;\">Coding and Marking Solutions<\/h3>\n<p>[\/et_pb_text][et_pb_button button_url=\"https:\/\/www.bestcode.co\/\" url_new_window=\"on\" button_text=\"www.bestcode.co\" button_alignment=\"center\" _builder_version=\"4.4.8\" custom_button=\"on\" button_text_size=\"13px\" button_bg_color=\"#1f3a7c\" button_border_width=\"2px\" button_border_color=\"#dfdfdf\" button_border_radius=\"15px\" button_letter_spacing=\"2px\" button_font=\"PT Sans Caption|700|||||||\" button_use_icon=\"off\" background_layout=\"dark\" custom_margin=\"7px|||0px|false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|phone\" custom_padding=\"7px|9px|7px|15px|false|false\"][\/et_pb_button][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_text content_tablet=\"<\/p>\n<h2 style=%22text-align: center;%22>About BestCode<\/h2>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/company%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Company<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/tradeshows%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Tradeshows<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/news%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>News<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/application-videos%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Application Videos<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/privacy-policy%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Privacy Policy<\/a><\/p>\n<p>\" content_phone=\"<\/p>\n<h2 style=%22text-align: center;%22>About BestCode<\/h2>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/company%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Company<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/tradeshows%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Tradeshows<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/news%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>News<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/application-videos%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Application Videos<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/privacy-policy%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Privacy Policy<\/a><\/p>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" text_font=\"PT Sans|600|||||||\" text_text_color=\"#1f3a7c\" text_letter_spacing=\"1px\" text_line_height=\"1em\" header_font=\"PT Sans Caption|||on|||||\" header_text_align=\"center\" header_text_color=\"#b6b6b6\" header_font_size=\"16px\" header_2_font=\"PT Sans Caption|||on|||||\" header_2_text_color=\"#919191\" header_2_font_size=\"14px\" custom_padding=\"|||1px|false|false\" custom_padding_tablet=\"\" custom_padding_phone=\"\" custom_padding_last_edited=\"on|phone\" link_option_url_new_window=\"on\"]<\/p>\n<h2 style=\"text-align: center;\">About BestCode<\/h2>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/company\" target=\"_blank\" rel=\"noopener noreferrer\">Company<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/tradeshows\" target=\"_blank\" rel=\"noopener noreferrer\">Tradeshows<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/news\" target=\"_blank\" rel=\"noopener noreferrer\">News<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/application-videos\" target=\"_blank\" rel=\"noopener noreferrer\">Application Videos<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/privacy-policy\" target=\"_blank\" rel=\"noopener noreferrer\">Privacy Policy<\/a><\/p>\n<p>[\/et_pb_text][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_text _builder_version=\"4.4.8\" text_font=\"PT Sans Caption|600||on|||||\" text_text_color=\"#1f3a7c\" text_letter_spacing=\"1px\" text_line_height=\"1em\" header_font=\"PT Sans||||||||\" header_text_align=\"center\" header_text_color=\"#b6b6b6\" header_font_size=\"18px\" header_2_font=\"PT Sans Caption||||||||\" header_2_text_align=\"center\" header_2_text_color=\"#919191\" header_2_font_size=\"14px\" text_orientation=\"center\" custom_padding=\"||8px||false|false\" link_option_url_new_window=\"on\"]<\/p>\n<h2 style=\"text-align: center;\">Follow BestCode<\/h2>\n<p>[\/et_pb_text][et_pb_social_media_follow _builder_version=\"4.4.8\" text_orientation=\"center\" custom_margin=\"-36px||||false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|desktop\"][et_pb_social_media_follow_network social_network=\"linkedin\" url=\"https:\/\/www.linkedin.com\/company\/bestcode\" _builder_version=\"4.4.8\" background_color=\"#007bb6\" follow_button=\"off\" url_new_window=\"on\"]linkedin[\/et_pb_social_media_follow_network][et_pb_social_media_follow_network social_network=\"instagram\" url=\"https:\/\/www.instagram.com\/bestcode_coding\/\" _builder_version=\"4.4.8\" background_color=\"#ea2c59\" follow_button=\"off\" url_new_window=\"on\"]instagram[\/et_pb_social_media_follow_network][et_pb_social_media_follow_network social_network=\"facebook\" url=\"https:\/\/www.facebook.com\/bestcodecoding\" _builder_version=\"4.4.8\" background_color=\"#3b5998\" follow_button=\"off\" url_new_window=\"on\"]facebook[\/et_pb_social_media_follow_network][et_pb_social_media_follow_network social_network=\"twitter\" url=\"https:\/\/twitter.com\/bestcodecoding\" _builder_version=\"4.4.8\" background_color=\"#00aced\" follow_button=\"off\" url_new_window=\"on\"]twitter[\/et_pb_social_media_follow_network][\/et_pb_social_media_follow][et_pb_text content_tablet=\"<\/p>\n<\/p>\n<h4 style=%22text-align: center;%22>Try-Before-You-Buy Options<\/p>\n<\/h4>\n<p>\" content_phone=\"<\/p>\n<\/p>\n<h4 style=%22text-align: center;%22>Try-Before-You-Buy Options<\/p>\n<\/h4>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_3_font=\"|700|||||||\" header_3_text_color=\"#1f3a7c\" header_3_line_height=\"1.1em\" header_4_font=\"Roboto Condensed|700|||||||\" header_4_text_color=\"#1f3a7c\" header_4_line_height=\"1.1em\" link_option_url=\"https:\/\/www.bestcode.co\/contact\" link_option_url_new_window=\"on\" header_4_font_tablet=\"\" header_4_font_phone=\"\" header_4_font_last_edited=\"on|desktop\" header_4_font_size_tablet=\"\" header_4_font_size_phone=\"\" header_4_font_size_last_edited=\"on|phone\"]<\/p>\n<h4 style=\"text-align: center;\"><a href=\"https:\/\/pei22.nvytes.co\/lp22\/51S27.html\" target=\"_blank\" rel=\"noopener noreferrer\"><\/a>Try Before You Buy Options<\/p>\n<\/h4>\n<p>[\/et_pb_text][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_text _builder_version=\"4.4.8\" text_font=\"|600|||||||\" text_text_color=\"#1f3a7c\" text_line_height=\"1em\" header_font=\"PT Sans||||||||\" header_text_color=\"#b6b6b6\" header_font_size=\"18px\" header_2_font=\"PT Sans Caption|||on|||||\" header_2_text_color=\"#919191\" header_2_font_size=\"14px\" header_2_letter_spacing=\"1px\" module_alignment=\"center\"]<\/p>\n<h2 style=\"text-align: center;\">Associations<\/h2>\n<p>[\/et_pb_text][et_pb_image src=\"https:\/\/support.bestcode.co\/wp-content\/uploads\/2020\/06\/memberPMMI.png\" alt=\"bestcode-pmmi-org-member\" title_text=\"PMMI Member\" url=\"https:\/\/pmmiprod3ebiz.personifycloud.com\/personifyebusiness\/MyAccount\/MemberDirectoryDetail.aspx?companyid=12195911\" url_new_window=\"on\" align=\"center\" src_tablet=\"https:\/\/support.bestcode.co\/wp-content\/uploads\/2020\/06\/memberPMMI.png\" src_phone=\"https:\/\/support.bestcode.co\/wp-content\/uploads\/2020\/06\/memberPMMI.png\" src_last_edited=\"on|phone\" show_bottom_space_tablet=\"\" show_bottom_space_phone=\"\" show_bottom_space_last_edited=\"on|phone\" align_tablet=\"center\" align_phone=\"center\" align_last_edited=\"on|desktop\" _builder_version=\"4.4.8\" custom_margin=\"-21px||||false|false\"][\/et_pb_image][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_blurb title=\"+1 817 349 8555\" use_icon=\"on\" font_icon=\"%%264%%\" icon_placement=\"left\" content_max_width=\"180px\" use_icon_font_size=\"on\" icon_font_size=\"18px\" content_tablet=\"\" content_phone=\"\" content_last_edited=\"on|phone\" content_max_width_tablet=\"\" content_max_width_phone=\"\" content_max_width_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_font_size=\"16px\" custom_margin=\"|0px||0px|false|false\" custom_padding=\"2px|||0px|false|false\" custom_padding_tablet=\"|||0px|false|false\" custom_padding_phone=\"|||0px|false|false\" custom_padding_last_edited=\"on|desktop\" header_text_align_tablet=\"\" header_text_align_phone=\"center\" header_text_align_last_edited=\"on|phone\"][\/et_pb_blurb][et_pb_blurb title=\"+1 817 349 8480\" use_icon=\"on\" font_icon=\"%%268%%\" icon_placement=\"left\" content_max_width=\"180px\" use_icon_font_size=\"on\" icon_font_size=\"18px\" content_max_width_tablet=\"\" content_max_width_phone=\"\" content_max_width_last_edited=\"on|desktop\" _builder_version=\"4.4.8\" header_font=\"PT Sans||||||||\" header_text_align=\"center\" header_font_size=\"16px\" width_tablet=\"\" width_phone=\"\" width_last_edited=\"on|tablet\" custom_margin=\"-14px|0px||0px|false|false\" custom_padding=\"|0px||0px|false|false\" custom_padding_tablet=\"\" custom_padding_phone=\"\" custom_padding_last_edited=\"on|phone\" header_font_tablet=\"\" header_font_phone=\"\" header_font_last_edited=\"on|phone\" header_text_align_tablet=\"\" header_text_align_phone=\"\" header_text_align_last_edited=\"on|tablet\" module_alignment_tablet=\"center\" module_alignment_phone=\"center\" module_alignment_last_edited=\"on|tablet\"][\/et_pb_blurb][et_pb_text content_tablet=\"<\/p>\n<\/p>\n<h4 style=%22text-align: center;%22>In Plant Demonstrations Available<\/h4>\n<\/p>\n<p>\" content_phone=\"<\/p>\n<\/p>\n<h4 style=%22text-align: center;%22>In Plant Demonstrations Available<\/h4>\n<\/p>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_3_font=\"|700|||||||\" header_3_text_color=\"#1f3a7c\" header_3_line_height=\"1.1em\" header_4_font=\"Roboto Condensed|700|||||||\" header_4_text_color=\"#1f3a7c\" header_4_line_height=\"1.1em\" link_option_url=\"https:\/\/www.bestcode.co\/contact\" link_option_url_new_window=\"on\" header_4_font_tablet=\"\" header_4_font_phone=\"\" header_4_font_last_edited=\"on|desktop\" header_4_font_size_tablet=\"\" header_4_font_size_phone=\"\" header_4_font_size_last_edited=\"on|phone\"]<\/p>\n<h4 style=\"text-align: center;\"><a href=\"https:\/\/pei22.nvytes.co\/lp22\/51S27.html\" target=\"_blank\" rel=\"noopener noreferrer\"><\/a>In Plant Demonstrations Available<\/h4>\n<p>[\/et_pb_text][\/et_pb_column][\/et_pb_row][\/et_pb_section][et_pb_section fb_built=\"1\" fullwidth=\"on\" _builder_version=\"4.4.8\" background_color=\"#b6b6b6\" height=\"75px\" height_tablet=\"\" height_phone=\"\" height_last_edited=\"on|phone\" custom_margin=\"||0px||false|false\" custom_padding=\"||0px||false|false\" hover_enabled=\"0\"][et_pb_fullwidth_header title=\"\u00a92024 BestCode | Designed and Manufactured by BestCode in Texas, USA\" _builder_version=\"4.4.8\" title_font=\"PT Sans Caption||||||||\" title_text_align=\"center\" title_font_size=\"13px\" title_line_height=\"1.1em\" background_color=\"#b6b6b6\" custom_margin=\"||0px||false|false\" custom_padding=\"18px||0px||false|false\" hover_enabled=\"0\" title_line_height_tablet=\"\" title_line_height_phone=\"1.7em\" title_line_height_last_edited=\"on|phone\"][\/et_pb_fullwidth_header][\/et_pb_section]<\/p>\n",["<p>[et_pb_section fb_built=\"1\" _builder_version=\"4.4.8\" background_color=\"#f2f2f3\" global_module=\"103\" saved_tabs=\"all\"][et_pb_row column_structure=\"1_5,1_5,1_5,1_5,1_5\" use_custom_gutter=\"on\" make_equal=\"on\" _builder_version=\"4.4.8\" background_color=\"rgba(0,0,0,0)\" width=\"100%\" max_width_tablet=\"\" max_width_phone=\"100%\" max_width_last_edited=\"on|phone\" module_alignment=\"center\" custom_margin=\"-33px||-22px||false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|phone\" custom_padding=\"38px|0px|29px|7px|false|false\" link_option_url_new_window=\"on\" module_alignment_tablet=\"center\" module_alignment_phone=\"\" module_alignment_last_edited=\"on|desktop\"][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\" link_option_url_new_window=\"on\"][et_pb_button button_url=\"mailto:info@bestcode.co\" url_new_window=\"on\" button_text=\"Email BestCode\" button_alignment=\"center\" _builder_version=\"4.4.8\" custom_button=\"on\" button_text_size=\"13px\" button_bg_color=\"#1f3a7c\" button_border_width=\"2px\" button_border_color=\"#dfdfdf\" button_border_radius=\"15px\" button_letter_spacing=\"2px\" button_font=\"PT Sans Caption|700|||||||\" button_icon=\"%%238%%\" button_icon_color=\"#adc837\" button_icon_placement=\"left\" button_on_hover=\"off\" background_layout=\"dark\" custom_margin=\"7px|||0px|false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|phone\" custom_padding=\"7px|9px|6px|26px|false|false\"][\/et_pb_button][et_pb_text content_tablet=\"<\/p>\n<h3 style=%22text-align: center;%22>Coding and Marking Solutions<\/h3>\n<p>\" content_phone=\"<\/p>\n<h3 style=%22text-align: center;%22>Coding and Marking Solutions<\/h3>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_3_font=\"|700|||||||\" header_3_text_color=\"#1f3a7c\" header_3_line_height=\"1.1em\" custom_margin=\"||7px|||\" custom_padding=\"||0px|||\" link_option_url=\"https:\/\/www.bestcode.co\/\" link_option_url_new_window=\"on\"]<\/p>\n<h3 style=\"text-align: center;\">Coding and Marking Solutions<\/h3>\n<p>[\/et_pb_text][et_pb_button button_url=\"https:\/\/www.bestcode.co\/\" url_new_window=\"on\" button_text=\"www.bestcode.co\" button_alignment=\"center\" _builder_version=\"4.4.8\" custom_button=\"on\" button_text_size=\"13px\" button_bg_color=\"#1f3a7c\" button_border_width=\"2px\" button_border_color=\"#dfdfdf\" button_border_radius=\"15px\" button_letter_spacing=\"2px\" button_font=\"PT Sans Caption|700|||||||\" button_use_icon=\"off\" background_layout=\"dark\" custom_margin=\"7px|||0px|false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|phone\" custom_padding=\"7px|9px|7px|15px|false|false\"][\/et_pb_button][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_text content_tablet=\"<\/p>\n<h2 style=%22text-align: center;%22>About BestCode<\/h2>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/company%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Company<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/tradeshows%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Tradeshows<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/news%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>News<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/application-videos%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Application Videos<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/privacy-policy%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Privacy Policy<\/a><\/p>\n<p>\" content_phone=\"<\/p>\n<h2 style=%22text-align: center;%22>About BestCode<\/h2>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/company%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Company<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/tradeshows%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Tradeshows<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/news%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>News<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/application-videos%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Application Videos<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/privacy-policy%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Privacy Policy<\/a><\/p>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" text_font=\"PT Sans|600|||||||\" text_text_color=\"#1f3a7c\" text_letter_spacing=\"1px\" text_line_height=\"1em\" header_font=\"PT Sans Caption|||on|||||\" header_text_align=\"center\" header_text_color=\"#b6b6b6\" header_font_size=\"16px\" header_2_font=\"PT Sans Caption|||on|||||\" header_2_text_color=\"#919191\" header_2_font_size=\"14px\" custom_padding=\"|||1px|false|false\" custom_padding_tablet=\"\" custom_padding_phone=\"\" custom_padding_last_edited=\"on|phone\" link_option_url_new_window=\"on\"]<\/p>\n<h2 style=\"text-align: center;\">About BestCode<\/h2>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/company\" target=\"_blank\" rel=\"noopener noreferrer\">Company<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/tradeshows\" target=\"_blank\" rel=\"noopener noreferrer\">Tradeshows<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/news\" target=\"_blank\" rel=\"noopener noreferrer\">News<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/application-videos\" target=\"_blank\" rel=\"noopener noreferrer\">Application Videos<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/privacy-policy\" target=\"_blank\" rel=\"noopener noreferrer\">Privacy Policy<\/a><\/p>\n<p>[\/et_pb_text][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_text _builder_version=\"4.4.8\" text_font=\"PT Sans Caption|600||on|||||\" text_text_color=\"#1f3a7c\" text_letter_spacing=\"1px\" text_line_height=\"1em\" header_font=\"PT Sans||||||||\" header_text_align=\"center\" header_text_color=\"#b6b6b6\" header_font_size=\"18px\" header_2_font=\"PT Sans Caption||||||||\" header_2_text_align=\"center\" header_2_text_color=\"#919191\" header_2_font_size=\"14px\" text_orientation=\"center\" custom_padding=\"||8px||false|false\" link_option_url_new_window=\"on\"]<\/p>\n<h2 style=\"text-align: center;\">Follow BestCode<\/h2>\n<p>[\/et_pb_text][et_pb_social_media_follow _builder_version=\"4.4.8\" text_orientation=\"center\" custom_margin=\"-36px||||false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|desktop\"][et_pb_social_media_follow_network social_network=\"linkedin\" url=\"https:\/\/www.linkedin.com\/company\/bestcode\" _builder_version=\"4.4.8\" background_color=\"#007bb6\" follow_button=\"off\" url_new_window=\"on\"]linkedin[\/et_pb_social_media_follow_network][et_pb_social_media_follow_network social_network=\"instagram\" url=\"https:\/\/www.instagram.com\/bestcode_coding\/\" _builder_version=\"4.4.8\" background_color=\"#ea2c59\" follow_button=\"off\" url_new_window=\"on\"]instagram[\/et_pb_social_media_follow_network][et_pb_social_media_follow_network social_network=\"facebook\" url=\"https:\/\/www.facebook.com\/bestcodecoding\" _builder_version=\"4.4.8\" background_color=\"#3b5998\" follow_button=\"off\" url_new_window=\"on\"]facebook[\/et_pb_social_media_follow_network][et_pb_social_media_follow_network social_network=\"twitter\" url=\"https:\/\/twitter.com\/bestcodecoding\" _builder_version=\"4.4.8\" background_color=\"#00aced\" follow_button=\"off\" url_new_window=\"on\"]twitter[\/et_pb_social_media_follow_network][\/et_pb_social_media_follow][et_pb_text content_tablet=\"<\/p>\n<\/p>\n<h4 style=%22text-align: center;%22>Try-Before-You-Buy Options<\/p>\n<\/h4>\n<p>\" content_phone=\"<\/p>\n<\/p>\n<h4 style=%22text-align: center;%22>Try-Before-You-Buy Options<\/p>\n<\/h4>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_3_font=\"|700|||||||\" header_3_text_color=\"#1f3a7c\" header_3_line_height=\"1.1em\" header_4_font=\"Roboto Condensed|700|||||||\" header_4_text_color=\"#1f3a7c\" header_4_line_height=\"1.1em\" link_option_url=\"https:\/\/www.bestcode.co\/contact\" link_option_url_new_window=\"on\" header_4_font_tablet=\"\" header_4_font_phone=\"\" header_4_font_last_edited=\"on|desktop\" header_4_font_size_tablet=\"\" header_4_font_size_phone=\"\" header_4_font_size_last_edited=\"on|phone\"]<\/p>\n<h4 style=\"text-align: center;\"><a href=\"https:\/\/pei22.nvytes.co\/lp22\/51S27.html\" target=\"_blank\" rel=\"noopener noreferrer\"><\/a>Try Before You Buy Options<\/p>\n<\/h4>\n<p>[\/et_pb_text][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_text _builder_version=\"4.4.8\" text_font=\"|600|||||||\" text_text_color=\"#1f3a7c\" text_line_height=\"1em\" header_font=\"PT Sans||||||||\" header_text_color=\"#b6b6b6\" header_font_size=\"18px\" header_2_font=\"PT Sans Caption|||on|||||\" header_2_text_color=\"#919191\" header_2_font_size=\"14px\" header_2_letter_spacing=\"1px\" module_alignment=\"center\"]<\/p>\n<h2 style=\"text-align: center;\">Associations<\/h2>\n<p>[\/et_pb_text][et_pb_image src=\"https:\/\/support.bestcode.co\/wp-content\/uploads\/2020\/06\/memberPMMI.png\" alt=\"bestcode-pmmi-org-member\" title_text=\"PMMI Member\" url=\"https:\/\/pmmiprod3ebiz.personifycloud.com\/personifyebusiness\/MyAccount\/MemberDirectoryDetail.aspx?companyid=12195911\" url_new_window=\"on\" align=\"center\" src_tablet=\"https:\/\/support.bestcode.co\/wp-content\/uploads\/2020\/06\/memberPMMI.png\" src_phone=\"https:\/\/support.bestcode.co\/wp-content\/uploads\/2020\/06\/memberPMMI.png\" src_last_edited=\"on|phone\" show_bottom_space_tablet=\"\" show_bottom_space_phone=\"\" show_bottom_space_last_edited=\"on|phone\" align_tablet=\"center\" align_phone=\"center\" align_last_edited=\"on|desktop\" _builder_version=\"4.4.8\" custom_margin=\"-21px||||false|false\"][\/et_pb_image][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_blurb title=\"+1 817 349 8555\" use_icon=\"on\" font_icon=\"%%264%%\" icon_placement=\"left\" content_max_width=\"180px\" use_icon_font_size=\"on\" icon_font_size=\"18px\" content_tablet=\"\" content_phone=\"\" content_last_edited=\"on|phone\" content_max_width_tablet=\"\" content_max_width_phone=\"\" content_max_width_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_font_size=\"16px\" custom_margin=\"|0px||0px|false|false\" custom_padding=\"2px|||0px|false|false\" custom_padding_tablet=\"|||0px|false|false\" custom_padding_phone=\"|||0px|false|false\" custom_padding_last_edited=\"on|desktop\" header_text_align_tablet=\"\" header_text_align_phone=\"center\" header_text_align_last_edited=\"on|phone\"][\/et_pb_blurb][et_pb_blurb title=\"+1 817 349 8480\" use_icon=\"on\" font_icon=\"%%268%%\" icon_placement=\"left\" content_max_width=\"180px\" use_icon_font_size=\"on\" icon_font_size=\"18px\" content_max_width_tablet=\"\" content_max_width_phone=\"\" content_max_width_last_edited=\"on|desktop\" _builder_version=\"4.4.8\" header_font=\"PT Sans||||||||\" header_text_align=\"center\" header_font_size=\"16px\" width_tablet=\"\" width_phone=\"\" width_last_edited=\"on|tablet\" custom_margin=\"-14px|0px||0px|false|false\" custom_padding=\"|0px||0px|false|false\" custom_padding_tablet=\"\" custom_padding_phone=\"\" custom_padding_last_edited=\"on|phone\" header_font_tablet=\"\" header_font_phone=\"\" header_font_last_edited=\"on|phone\" header_text_align_tablet=\"\" header_text_align_phone=\"\" header_text_align_last_edited=\"on|tablet\" module_alignment_tablet=\"center\" module_alignment_phone=\"center\" module_alignment_last_edited=\"on|tablet\"][\/et_pb_blurb][et_pb_text content_tablet=\"<\/p>\n<\/p>\n<h4 style=%22text-align: center;%22>In Plant Demonstrations Available<\/h4>\n<\/p>\n<p>\" content_phone=\"<\/p>\n<\/p>\n<h4 style=%22text-align: center;%22>In Plant Demonstrations Available<\/h4>\n<\/p>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_3_font=\"|700|||||||\" header_3_text_color=\"#1f3a7c\" header_3_line_height=\"1.1em\" header_4_font=\"Roboto Condensed|700|||||||\" header_4_text_color=\"#1f3a7c\" header_4_line_height=\"1.1em\" link_option_url=\"https:\/\/www.bestcode.co\/contact\" link_option_url_new_window=\"on\" header_4_font_tablet=\"\" header_4_font_phone=\"\" header_4_font_last_edited=\"on|desktop\" header_4_font_size_tablet=\"\" header_4_font_size_phone=\"\" header_4_font_size_last_edited=\"on|phone\"]<\/p>\n<h4 style=\"text-align: center;\"><a href=\"https:\/\/pei22.nvytes.co\/lp22\/51S27.html\" target=\"_blank\" rel=\"noopener noreferrer\"><\/a>In Plant Demonstrations Available<\/h4>\n<p>[\/et_pb_text][\/et_pb_column][\/et_pb_row][\/et_pb_section][et_pb_section fb_built=\"1\" fullwidth=\"on\" _builder_version=\"4.4.8\" background_color=\"#b6b6b6\" height=\"75px\" height_tablet=\"\" height_phone=\"\" height_last_edited=\"on|phone\" custom_margin=\"||0px||false|false\" custom_padding=\"||0px||false|false\" hover_enabled=\"0\"][et_pb_fullwidth_header title=\"\u00a92024 BestCode | Designed and Manufactured by BestCode in Texas, USA\" _builder_version=\"4.4.8\" title_font=\"PT Sans Caption||||||||\" title_text_align=\"center\" title_font_size=\"13px\" title_line_height=\"1.1em\" background_color=\"#b6b6b6\" custom_margin=\"||0px||false|false\" custom_padding=\"18px||0px||false|false\" hover_enabled=\"0\" title_line_height_tablet=\"\" title_line_height_phone=\"1.7em\" title_line_height_last_edited=\"on|phone\"][\/et_pb_fullwidth_header][\/et_pb_section]<\/p>\n"]]

#3 /home/bestcodevps/support.bestcode.co/wp-content/themes/divi/includes/builder/core.php(20): apply_filters() Arguments ["et_builder_render_layout","[et_pb_section fb_built=\"1\" _builder_version=\"4.4.8\" background_color=\"#f2f2f3\" global_module=\"103\" saved_tabs=\"all\"][et_pb_row column_structure=\"1_5,1_5,1_5,1_5,1_5\" use_custom_gutter=\"on\" make_equal=\"on\" _builder_version=\"4.4.8\" background_color=\"rgba(0,0,0,0)\" width=\"100%\" max_width_tablet=\"\" max_width_phone=\"100%\" max_width_last_edited=\"on|phone\" module_alignment=\"center\" custom_margin=\"-33px||-22px||false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|phone\" custom_padding=\"38px|0px|29px|7px|false|false\" link_option_url_new_window=\"on\" module_alignment_tablet=\"center\" module_alignment_phone=\"\" module_alignment_last_edited=\"on|desktop\"][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\" link_option_url_new_window=\"on\"][et_pb_button button_url=\"mailto:info@bestcode.co\" url_new_window=\"on\" button_text=\"Email BestCode\" button_alignment=\"center\" _builder_version=\"4.4.8\" custom_button=\"on\" button_text_size=\"13px\" button_bg_color=\"#1f3a7c\" button_border_width=\"2px\" button_border_color=\"#dfdfdf\" button_border_radius=\"15px\" button_letter_spacing=\"2px\" button_font=\"PT Sans Caption|700|||||||\" button_icon=\"%%238%%\" button_icon_color=\"#adc837\" button_icon_placement=\"left\" button_on_hover=\"off\" background_layout=\"dark\" custom_margin=\"7px|||0px|false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|phone\" custom_padding=\"7px|9px|6px|26px|false|false\"][\/et_pb_button][et_pb_text content_tablet=\"<\/p>\n<h3 style=%22text-align: center;%22>Coding and Marking Solutions<\/h3>\n<p>\" content_phone=\"<\/p>\n<h3 style=%22text-align: center;%22>Coding and Marking Solutions<\/h3>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_3_font=\"|700|||||||\" header_3_text_color=\"#1f3a7c\" header_3_line_height=\"1.1em\" custom_margin=\"||7px|||\" custom_padding=\"||0px|||\" link_option_url=\"https:\/\/www.bestcode.co\/\" link_option_url_new_window=\"on\"]<h3 style=\"text-align: center;\">Coding and Marking Solutions<\/h3>[\/et_pb_text][et_pb_button button_url=\"https:\/\/www.bestcode.co\/\" url_new_window=\"on\" button_text=\"www.bestcode.co\" button_alignment=\"center\" _builder_version=\"4.4.8\" custom_button=\"on\" button_text_size=\"13px\" button_bg_color=\"#1f3a7c\" button_border_width=\"2px\" button_border_color=\"#dfdfdf\" button_border_radius=\"15px\" button_letter_spacing=\"2px\" button_font=\"PT Sans Caption|700|||||||\" button_use_icon=\"off\" background_layout=\"dark\" custom_margin=\"7px|||0px|false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|phone\" custom_padding=\"7px|9px|7px|15px|false|false\"][\/et_pb_button][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_text content_tablet=\"<\/p>\n<h2 style=%22text-align: center;%22>About BestCode<\/h2>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/company%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Company<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/tradeshows%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Tradeshows<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/news%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>News<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/application-videos%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Application Videos<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/privacy-policy%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Privacy Policy<\/a><\/p>\n<p>\" content_phone=\"<\/p>\n<h2 style=%22text-align: center;%22>About BestCode<\/h2>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/company%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Company<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/tradeshows%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Tradeshows<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/news%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>News<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/application-videos%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Application Videos<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/privacy-policy%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Privacy Policy<\/a><\/p>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" text_font=\"PT Sans|600|||||||\" text_text_color=\"#1f3a7c\" text_letter_spacing=\"1px\" text_line_height=\"1em\" header_font=\"PT Sans Caption|||on|||||\" header_text_align=\"center\" header_text_color=\"#b6b6b6\" header_font_size=\"16px\" header_2_font=\"PT Sans Caption|||on|||||\" header_2_text_color=\"#919191\" header_2_font_size=\"14px\" custom_padding=\"|||1px|false|false\" custom_padding_tablet=\"\" custom_padding_phone=\"\" custom_padding_last_edited=\"on|phone\" link_option_url_new_window=\"on\"]<h2 style=\"text-align: center;\">About BestCode<\/h2>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/company\" target=\"_blank\" rel=\"noopener noreferrer\">Company<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/tradeshows\" target=\"_blank\" rel=\"noopener noreferrer\">Tradeshows<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/news\" target=\"_blank\" rel=\"noopener noreferrer\">News<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/application-videos\" target=\"_blank\" rel=\"noopener noreferrer\">Application Videos<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/privacy-policy\" target=\"_blank\" rel=\"noopener noreferrer\">Privacy Policy<\/a><\/p>[\/et_pb_text][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_text _builder_version=\"4.4.8\" text_font=\"PT Sans Caption|600||on|||||\" text_text_color=\"#1f3a7c\" text_letter_spacing=\"1px\" text_line_height=\"1em\" header_font=\"PT Sans||||||||\" header_text_align=\"center\" header_text_color=\"#b6b6b6\" header_font_size=\"18px\" header_2_font=\"PT Sans Caption||||||||\" header_2_text_align=\"center\" header_2_text_color=\"#919191\" header_2_font_size=\"14px\" text_orientation=\"center\" custom_padding=\"||8px||false|false\" link_option_url_new_window=\"on\"]<h2 style=\"text-align: center;\">Follow BestCode<\/h2>[\/et_pb_text][et_pb_social_media_follow _builder_version=\"4.4.8\" text_orientation=\"center\" custom_margin=\"-36px||||false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|desktop\"][et_pb_social_media_follow_network social_network=\"linkedin\" url=\"https:\/\/www.linkedin.com\/company\/bestcode\" _builder_version=\"4.4.8\" background_color=\"#007bb6\" follow_button=\"off\" url_new_window=\"on\"]linkedin[\/et_pb_social_media_follow_network][et_pb_social_media_follow_network social_network=\"instagram\" url=\"https:\/\/www.instagram.com\/bestcode_coding\/\" _builder_version=\"4.4.8\" background_color=\"#ea2c59\" follow_button=\"off\" url_new_window=\"on\"]instagram[\/et_pb_social_media_follow_network][et_pb_social_media_follow_network social_network=\"facebook\" url=\"https:\/\/www.facebook.com\/bestcodecoding\" _builder_version=\"4.4.8\" background_color=\"#3b5998\" follow_button=\"off\" url_new_window=\"on\"]facebook[\/et_pb_social_media_follow_network][et_pb_social_media_follow_network social_network=\"twitter\" url=\"https:\/\/twitter.com\/bestcodecoding\" _builder_version=\"4.4.8\" background_color=\"#00aced\" follow_button=\"off\" url_new_window=\"on\"]twitter[\/et_pb_social_media_follow_network][\/et_pb_social_media_follow][et_pb_text content_tablet=\"<\/p>\n<p> <\/p>\n<h4 style=%22text-align: center;%22>Try-Before-You-Buy Options<\/p>\n<\/h4>\n<p> <\/p>\n<p>\" content_phone=\"<\/p>\n<p> <\/p>\n<h4 style=%22text-align: center;%22>Try-Before-You-Buy Options<\/p>\n<\/h4>\n<p> <\/p>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_3_font=\"|700|||||||\" header_3_text_color=\"#1f3a7c\" header_3_line_height=\"1.1em\" header_4_font=\"Roboto Condensed|700|||||||\" header_4_text_color=\"#1f3a7c\" header_4_line_height=\"1.1em\" link_option_url=\"https:\/\/www.bestcode.co\/contact\" link_option_url_new_window=\"on\" header_4_font_tablet=\"\" header_4_font_phone=\"\" header_4_font_last_edited=\"on|desktop\" header_4_font_size_tablet=\"\" header_4_font_size_phone=\"\" header_4_font_size_last_edited=\"on|phone\"]<h4 style=\"text-align: center;\"><a href=\"https:\/\/pei22.nvytes.co\/lp22\/51S27.html\" target=\"_blank\" rel=\"noopener noreferrer\"><\/a>Try Before You Buy Options<\/p>\n<\/h4>[\/et_pb_text][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_text _builder_version=\"4.4.8\" text_font=\"|600|||||||\" text_text_color=\"#1f3a7c\" text_line_height=\"1em\" header_font=\"PT Sans||||||||\" header_text_color=\"#b6b6b6\" header_font_size=\"18px\" header_2_font=\"PT Sans Caption|||on|||||\" header_2_text_color=\"#919191\" header_2_font_size=\"14px\" header_2_letter_spacing=\"1px\" module_alignment=\"center\"]<h2 style=\"text-align: center;\">Associations<\/h2>[\/et_pb_text][et_pb_image src=\"https:\/\/support.bestcode.co\/wp-content\/uploads\/2020\/06\/memberPMMI.png\" alt=\"bestcode-pmmi-org-member\" title_text=\"PMMI Member\" url=\"https:\/\/pmmiprod3ebiz.personifycloud.com\/personifyebusiness\/MyAccount\/MemberDirectoryDetail.aspx?companyid=12195911\" url_new_window=\"on\" align=\"center\" src_tablet=\"https:\/\/support.bestcode.co\/wp-content\/uploads\/2020\/06\/memberPMMI.png\" src_phone=\"https:\/\/support.bestcode.co\/wp-content\/uploads\/2020\/06\/memberPMMI.png\" src_last_edited=\"on|phone\" show_bottom_space_tablet=\"\" show_bottom_space_phone=\"\" show_bottom_space_last_edited=\"on|phone\" align_tablet=\"center\" align_phone=\"center\" align_last_edited=\"on|desktop\" _builder_version=\"4.4.8\" custom_margin=\"-21px||||false|false\"][\/et_pb_image][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_blurb title=\"+1 817 349 8555\" use_icon=\"on\" font_icon=\"%%264%%\" icon_placement=\"left\" content_max_width=\"180px\" use_icon_font_size=\"on\" icon_font_size=\"18px\" content_tablet=\"\" content_phone=\"\" content_last_edited=\"on|phone\" content_max_width_tablet=\"\" content_max_width_phone=\"\" content_max_width_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_font_size=\"16px\" custom_margin=\"|0px||0px|false|false\" custom_padding=\"2px|||0px|false|false\" custom_padding_tablet=\"|||0px|false|false\" custom_padding_phone=\"|||0px|false|false\" custom_padding_last_edited=\"on|desktop\" header_text_align_tablet=\"\" header_text_align_phone=\"center\" header_text_align_last_edited=\"on|phone\"][\/et_pb_blurb][et_pb_blurb title=\"+1 817 349 8480\" use_icon=\"on\" font_icon=\"%%268%%\" icon_placement=\"left\" content_max_width=\"180px\" use_icon_font_size=\"on\" icon_font_size=\"18px\" content_max_width_tablet=\"\" content_max_width_phone=\"\" content_max_width_last_edited=\"on|desktop\" _builder_version=\"4.4.8\" header_font=\"PT Sans||||||||\" header_text_align=\"center\" header_font_size=\"16px\" width_tablet=\"\" width_phone=\"\" width_last_edited=\"on|tablet\" custom_margin=\"-14px|0px||0px|false|false\" custom_padding=\"|0px||0px|false|false\" custom_padding_tablet=\"\" custom_padding_phone=\"\" custom_padding_last_edited=\"on|phone\" header_font_tablet=\"\" header_font_phone=\"\" header_font_last_edited=\"on|phone\" header_text_align_tablet=\"\" header_text_align_phone=\"\" header_text_align_last_edited=\"on|tablet\" module_alignment_tablet=\"center\" module_alignment_phone=\"center\" module_alignment_last_edited=\"on|tablet\"][\/et_pb_blurb][et_pb_text content_tablet=\"<\/p>\n<p> <\/p>\n<h4 style=%22text-align: center;%22>In Plant Demonstrations Available<\/h4>\n<p> <\/p>\n<p>\" content_phone=\"<\/p>\n<p> <\/p>\n<h4 style=%22text-align: center;%22>In Plant Demonstrations Available<\/h4>\n<p> <\/p>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_3_font=\"|700|||||||\" header_3_text_color=\"#1f3a7c\" header_3_line_height=\"1.1em\" header_4_font=\"Roboto Condensed|700|||||||\" header_4_text_color=\"#1f3a7c\" header_4_line_height=\"1.1em\" link_option_url=\"https:\/\/www.bestcode.co\/contact\" link_option_url_new_window=\"on\" header_4_font_tablet=\"\" header_4_font_phone=\"\" header_4_font_last_edited=\"on|desktop\" header_4_font_size_tablet=\"\" header_4_font_size_phone=\"\" header_4_font_size_last_edited=\"on|phone\"]<h4 style=\"text-align: center;\"><a href=\"https:\/\/pei22.nvytes.co\/lp22\/51S27.html\" target=\"_blank\" rel=\"noopener noreferrer\"><\/a>In Plant Demonstrations Available<\/h4>[\/et_pb_text][\/et_pb_column][\/et_pb_row][\/et_pb_section][et_pb_section fb_built=\"1\" fullwidth=\"on\" _builder_version=\"4.4.8\" background_color=\"#b6b6b6\" height=\"75px\" height_tablet=\"\" height_phone=\"\" height_last_edited=\"on|phone\" custom_margin=\"||0px||false|false\" custom_padding=\"||0px||false|false\" hover_enabled=\"0\"][et_pb_fullwidth_header title=\"\u00a92024 BestCode | Designed and Manufactured by BestCode in Texas, USA\" _builder_version=\"4.4.8\" title_font=\"PT Sans Caption||||||||\" title_text_align=\"center\" title_font_size=\"13px\" title_line_height=\"1.1em\" background_color=\"#b6b6b6\" custom_margin=\"||0px||false|false\" custom_padding=\"18px||0px||false|false\" hover_enabled=\"0\" title_line_height_tablet=\"\" title_line_height_phone=\"1.7em\" title_line_height_last_edited=\"on|phone\"][\/et_pb_fullwidth_header][\/et_pb_section]"]

#4 /home/bestcodevps/support.bestcode.co/wp-content/themes/divi/includes/builder/frontend-builder/theme-builder/frontend.php(329): et_builder_render_layout() Arguments ["[et_pb_section fb_built=\"1\" _builder_version=\"4.4.8\" background_color=\"#f2f2f3\" global_module=\"103\" saved_tabs=\"all\"][et_pb_row column_structure=\"1_5,1_5,1_5,1_5,1_5\" use_custom_gutter=\"on\" make_equal=\"on\" _builder_version=\"4.4.8\" background_color=\"rgba(0,0,0,0)\" width=\"100%\" max_width_tablet=\"\" max_width_phone=\"100%\" max_width_last_edited=\"on|phone\" module_alignment=\"center\" custom_margin=\"-33px||-22px||false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|phone\" custom_padding=\"38px|0px|29px|7px|false|false\" link_option_url_new_window=\"on\" module_alignment_tablet=\"center\" module_alignment_phone=\"\" module_alignment_last_edited=\"on|desktop\"][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\" link_option_url_new_window=\"on\"][et_pb_button button_url=\"mailto:info@bestcode.co\" url_new_window=\"on\" button_text=\"Email BestCode\" button_alignment=\"center\" _builder_version=\"4.4.8\" custom_button=\"on\" button_text_size=\"13px\" button_bg_color=\"#1f3a7c\" button_border_width=\"2px\" button_border_color=\"#dfdfdf\" button_border_radius=\"15px\" button_letter_spacing=\"2px\" button_font=\"PT Sans Caption|700|||||||\" button_icon=\"%%238%%\" button_icon_color=\"#adc837\" button_icon_placement=\"left\" button_on_hover=\"off\" background_layout=\"dark\" custom_margin=\"7px|||0px|false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|phone\" custom_padding=\"7px|9px|6px|26px|false|false\"][\/et_pb_button][et_pb_text content_tablet=\"<\/p>\n<h3 style=%22text-align: center;%22>Coding and Marking Solutions<\/h3>\n<p>\" content_phone=\"<\/p>\n<h3 style=%22text-align: center;%22>Coding and Marking Solutions<\/h3>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_3_font=\"|700|||||||\" header_3_text_color=\"#1f3a7c\" header_3_line_height=\"1.1em\" custom_margin=\"||7px|||\" custom_padding=\"||0px|||\" link_option_url=\"https:\/\/www.bestcode.co\/\" link_option_url_new_window=\"on\"]<h3 style=\"text-align: center;\">Coding and Marking Solutions<\/h3>[\/et_pb_text][et_pb_button button_url=\"https:\/\/www.bestcode.co\/\" url_new_window=\"on\" button_text=\"www.bestcode.co\" button_alignment=\"center\" _builder_version=\"4.4.8\" custom_button=\"on\" button_text_size=\"13px\" button_bg_color=\"#1f3a7c\" button_border_width=\"2px\" button_border_color=\"#dfdfdf\" button_border_radius=\"15px\" button_letter_spacing=\"2px\" button_font=\"PT Sans Caption|700|||||||\" button_use_icon=\"off\" background_layout=\"dark\" custom_margin=\"7px|||0px|false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|phone\" custom_padding=\"7px|9px|7px|15px|false|false\"][\/et_pb_button][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_text content_tablet=\"<\/p>\n<h2 style=%22text-align: center;%22>About BestCode<\/h2>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/company%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Company<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/tradeshows%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Tradeshows<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/news%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>News<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/application-videos%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Application Videos<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/privacy-policy%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Privacy Policy<\/a><\/p>\n<p>\" content_phone=\"<\/p>\n<h2 style=%22text-align: center;%22>About BestCode<\/h2>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/company%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Company<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/tradeshows%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Tradeshows<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/news%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>News<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/application-videos%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Application Videos<\/a><\/p>\n<p style=%22text-align: center;%22><a href=%22https:\/\/www.bestcode.co\/privacy-policy%22 data-et-target-link=%22_blank%22 rel=%22noopener noreferrer%22>Privacy Policy<\/a><\/p>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" text_font=\"PT Sans|600|||||||\" text_text_color=\"#1f3a7c\" text_letter_spacing=\"1px\" text_line_height=\"1em\" header_font=\"PT Sans Caption|||on|||||\" header_text_align=\"center\" header_text_color=\"#b6b6b6\" header_font_size=\"16px\" header_2_font=\"PT Sans Caption|||on|||||\" header_2_text_color=\"#919191\" header_2_font_size=\"14px\" custom_padding=\"|||1px|false|false\" custom_padding_tablet=\"\" custom_padding_phone=\"\" custom_padding_last_edited=\"on|phone\" link_option_url_new_window=\"on\"]<h2 style=\"text-align: center;\">About BestCode<\/h2>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/company\" target=\"_blank\" rel=\"noopener noreferrer\">Company<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/tradeshows\" target=\"_blank\" rel=\"noopener noreferrer\">Tradeshows<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/news\" target=\"_blank\" rel=\"noopener noreferrer\">News<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/application-videos\" target=\"_blank\" rel=\"noopener noreferrer\">Application Videos<\/a><\/p>\n<p style=\"text-align: center;\"><a href=\"https:\/\/www.bestcode.co\/privacy-policy\" target=\"_blank\" rel=\"noopener noreferrer\">Privacy Policy<\/a><\/p>[\/et_pb_text][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_text _builder_version=\"4.4.8\" text_font=\"PT Sans Caption|600||on|||||\" text_text_color=\"#1f3a7c\" text_letter_spacing=\"1px\" text_line_height=\"1em\" header_font=\"PT Sans||||||||\" header_text_align=\"center\" header_text_color=\"#b6b6b6\" header_font_size=\"18px\" header_2_font=\"PT Sans Caption||||||||\" header_2_text_align=\"center\" header_2_text_color=\"#919191\" header_2_font_size=\"14px\" text_orientation=\"center\" custom_padding=\"||8px||false|false\" link_option_url_new_window=\"on\"]<h2 style=\"text-align: center;\">Follow BestCode<\/h2>[\/et_pb_text][et_pb_social_media_follow _builder_version=\"4.4.8\" text_orientation=\"center\" custom_margin=\"-36px||||false|false\" custom_margin_tablet=\"\" custom_margin_phone=\"\" custom_margin_last_edited=\"on|desktop\"][et_pb_social_media_follow_network social_network=\"linkedin\" url=\"https:\/\/www.linkedin.com\/company\/bestcode\" _builder_version=\"4.4.8\" background_color=\"#007bb6\" follow_button=\"off\" url_new_window=\"on\"]linkedin[\/et_pb_social_media_follow_network][et_pb_social_media_follow_network social_network=\"instagram\" url=\"https:\/\/www.instagram.com\/bestcode_coding\/\" _builder_version=\"4.4.8\" background_color=\"#ea2c59\" follow_button=\"off\" url_new_window=\"on\"]instagram[\/et_pb_social_media_follow_network][et_pb_social_media_follow_network social_network=\"facebook\" url=\"https:\/\/www.facebook.com\/bestcodecoding\" _builder_version=\"4.4.8\" background_color=\"#3b5998\" follow_button=\"off\" url_new_window=\"on\"]facebook[\/et_pb_social_media_follow_network][et_pb_social_media_follow_network social_network=\"twitter\" url=\"https:\/\/twitter.com\/bestcodecoding\" _builder_version=\"4.4.8\" background_color=\"#00aced\" follow_button=\"off\" url_new_window=\"on\"]twitter[\/et_pb_social_media_follow_network][\/et_pb_social_media_follow][et_pb_text content_tablet=\"<\/p>\n<p> <\/p>\n<h4 style=%22text-align: center;%22>Try-Before-You-Buy Options<\/p>\n<\/h4>\n<p> <\/p>\n<p>\" content_phone=\"<\/p>\n<p> <\/p>\n<h4 style=%22text-align: center;%22>Try-Before-You-Buy Options<\/p>\n<\/h4>\n<p> <\/p>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_3_font=\"|700|||||||\" header_3_text_color=\"#1f3a7c\" header_3_line_height=\"1.1em\" header_4_font=\"Roboto Condensed|700|||||||\" header_4_text_color=\"#1f3a7c\" header_4_line_height=\"1.1em\" link_option_url=\"https:\/\/www.bestcode.co\/contact\" link_option_url_new_window=\"on\" header_4_font_tablet=\"\" header_4_font_phone=\"\" header_4_font_last_edited=\"on|desktop\" header_4_font_size_tablet=\"\" header_4_font_size_phone=\"\" header_4_font_size_last_edited=\"on|phone\"]<h4 style=\"text-align: center;\"><a href=\"https:\/\/pei22.nvytes.co\/lp22\/51S27.html\" target=\"_blank\" rel=\"noopener noreferrer\"><\/a>Try Before You Buy Options<\/p>\n<\/h4>[\/et_pb_text][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_text _builder_version=\"4.4.8\" text_font=\"|600|||||||\" text_text_color=\"#1f3a7c\" text_line_height=\"1em\" header_font=\"PT Sans||||||||\" header_text_color=\"#b6b6b6\" header_font_size=\"18px\" header_2_font=\"PT Sans Caption|||on|||||\" header_2_text_color=\"#919191\" header_2_font_size=\"14px\" header_2_letter_spacing=\"1px\" module_alignment=\"center\"]<h2 style=\"text-align: center;\">Associations<\/h2>[\/et_pb_text][et_pb_image src=\"https:\/\/support.bestcode.co\/wp-content\/uploads\/2020\/06\/memberPMMI.png\" alt=\"bestcode-pmmi-org-member\" title_text=\"PMMI Member\" url=\"https:\/\/pmmiprod3ebiz.personifycloud.com\/personifyebusiness\/MyAccount\/MemberDirectoryDetail.aspx?companyid=12195911\" url_new_window=\"on\" align=\"center\" src_tablet=\"https:\/\/support.bestcode.co\/wp-content\/uploads\/2020\/06\/memberPMMI.png\" src_phone=\"https:\/\/support.bestcode.co\/wp-content\/uploads\/2020\/06\/memberPMMI.png\" src_last_edited=\"on|phone\" show_bottom_space_tablet=\"\" show_bottom_space_phone=\"\" show_bottom_space_last_edited=\"on|phone\" align_tablet=\"center\" align_phone=\"center\" align_last_edited=\"on|desktop\" _builder_version=\"4.4.8\" custom_margin=\"-21px||||false|false\"][\/et_pb_image][\/et_pb_column][et_pb_column type=\"1_5\" _builder_version=\"4.4.8\"][et_pb_blurb title=\"+1 817 349 8555\" use_icon=\"on\" font_icon=\"%%264%%\" icon_placement=\"left\" content_max_width=\"180px\" use_icon_font_size=\"on\" icon_font_size=\"18px\" content_tablet=\"\" content_phone=\"\" content_last_edited=\"on|phone\" content_max_width_tablet=\"\" content_max_width_phone=\"\" content_max_width_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_font_size=\"16px\" custom_margin=\"|0px||0px|false|false\" custom_padding=\"2px|||0px|false|false\" custom_padding_tablet=\"|||0px|false|false\" custom_padding_phone=\"|||0px|false|false\" custom_padding_last_edited=\"on|desktop\" header_text_align_tablet=\"\" header_text_align_phone=\"center\" header_text_align_last_edited=\"on|phone\"][\/et_pb_blurb][et_pb_blurb title=\"+1 817 349 8480\" use_icon=\"on\" font_icon=\"%%268%%\" icon_placement=\"left\" content_max_width=\"180px\" use_icon_font_size=\"on\" icon_font_size=\"18px\" content_max_width_tablet=\"\" content_max_width_phone=\"\" content_max_width_last_edited=\"on|desktop\" _builder_version=\"4.4.8\" header_font=\"PT Sans||||||||\" header_text_align=\"center\" header_font_size=\"16px\" width_tablet=\"\" width_phone=\"\" width_last_edited=\"on|tablet\" custom_margin=\"-14px|0px||0px|false|false\" custom_padding=\"|0px||0px|false|false\" custom_padding_tablet=\"\" custom_padding_phone=\"\" custom_padding_last_edited=\"on|phone\" header_font_tablet=\"\" header_font_phone=\"\" header_font_last_edited=\"on|phone\" header_text_align_tablet=\"\" header_text_align_phone=\"\" header_text_align_last_edited=\"on|tablet\" module_alignment_tablet=\"center\" module_alignment_phone=\"center\" module_alignment_last_edited=\"on|tablet\"][\/et_pb_blurb][et_pb_text content_tablet=\"<\/p>\n<p> <\/p>\n<h4 style=%22text-align: center;%22>In Plant Demonstrations Available<\/h4>\n<p> <\/p>\n<p>\" content_phone=\"<\/p>\n<p> <\/p>\n<h4 style=%22text-align: center;%22>In Plant Demonstrations Available<\/h4>\n<p> <\/p>\n<p>\" content_last_edited=\"on|phone\" _builder_version=\"4.4.8\" header_3_font=\"|700|||||||\" header_3_text_color=\"#1f3a7c\" header_3_line_height=\"1.1em\" header_4_font=\"Roboto Condensed|700|||||||\" header_4_text_color=\"#1f3a7c\" header_4_line_height=\"1.1em\" link_option_url=\"https:\/\/www.bestcode.co\/contact\" link_option_url_new_window=\"on\" header_4_font_tablet=\"\" header_4_font_phone=\"\" header_4_font_last_edited=\"on|desktop\" header_4_font_size_tablet=\"\" header_4_font_size_phone=\"\" header_4_font_size_last_edited=\"on|phone\"]<h4 style=\"text-align: center;\"><a href=\"https:\/\/pei22.nvytes.co\/lp22\/51S27.html\" target=\"_blank\" rel=\"noopener noreferrer\"><\/a>In Plant Demonstrations Available<\/h4>[\/et_pb_text][\/et_pb_column][\/et_pb_row][\/et_pb_section][et_pb_section fb_built=\"1\" fullwidth=\"on\" _builder_version=\"4.4.8\" background_color=\"#b6b6b6\" height=\"75px\" height_tablet=\"\" height_phone=\"\" height_last_edited=\"on|phone\" custom_margin=\"||0px||false|false\" custom_padding=\"||0px||false|false\" hover_enabled=\"0\"][et_pb_fullwidth_header title=\"\u00a92024 BestCode | Designed and Manufactured by BestCode in Texas, USA\" _builder_version=\"4.4.8\" title_font=\"PT Sans Caption||||||||\" title_text_align=\"center\" title_font_size=\"13px\" title_line_height=\"1.1em\" background_color=\"#b6b6b6\" custom_margin=\"||0px||false|false\" custom_padding=\"18px||0px||false|false\" hover_enabled=\"0\" title_line_height_tablet=\"\" title_line_height_phone=\"1.7em\" title_line_height_last_edited=\"on|phone\"][\/et_pb_fullwidth_header][\/et_pb_section]"]

#5 /home/bestcodevps/support.bestcode.co/wp-content/themes/divi/includes/builder/frontend-builder/theme-builder/frontend.php(498): et_theme_builder_frontend_render_layout() Arguments ["et_footer_layout",168]

#6 /home/bestcodevps/support.bestcode.co/wp-content/themes/divi/includes/builder/frontend-builder/theme-builder/frontend-footer-template.php(5): et_theme_builder_frontend_render_footer() Arguments [168,true,161]

#7 /home/bestcodevps/support.bestcode.co/wp-content/themes/divi/includes/builder/frontend-builder/theme-builder/frontend.php(204): require_once() Arguments ["\/home\/bestcodevps\/support.bestcode.co\/wp-content\/themes\/divi\/includes\/builder\/frontend-builder\/theme-builder\/frontend-footer-template.php"]

#8 /home/bestcodevps/support.bestcode.co/wp-content/themes/divi/includes/builder/frontend-builder/theme-builder/frontend.php(252): et_theme_builder_frontend_override_partial() Arguments ["footer","","wp_footer"]

#9 /home/bestcodevps/support.bestcode.co/wp-includes/class-wp-hook.php(326): et_theme_builder_frontend_override_footer() Arguments [null]

#10 /home/bestcodevps/support.bestcode.co/wp-includes/class-wp-hook.php(348): WP_Hook::apply_filters() Arguments ["",[null,[]]]

#11 /home/bestcodevps/support.bestcode.co/wp-includes/plugin.php(517): WP_Hook::do_action() Arguments [[null,[]]]

#12 /home/bestcodevps/support.bestcode.co/wp-includes/general-template.php(82): do_action() Arguments ["get_footer",null,[]]

#13 /home/bestcodevps/support.bestcode.co/wp-content/themes/divi/page.php(75): get_footer()

#14 /home/bestcodevps/support.bestcode.co/wp-includes/template-loader.php(106): include() Arguments ["\/home\/bestcodevps\/support.bestcode.co\/wp-content\/themes\/divi\/page.php"]

#15 /home/bestcodevps/support.bestcode.co/wp-blog-header.php(19): require_once() Arguments ["\/home\/bestcodevps\/support.bestcode.co\/wp-includes\/template-loader.php"]

#16 /home/bestcodevps/support.bestcode.co/index.php(17): require() Arguments ["\/home\/bestcodevps\/support.bestcode.co\/wp-blog-header.php"]

#17 {main}

thrown in /home/bestcodevps/support.bestcode.co/wp-includes/deprecated.php on line 4013